The EU-funded project PEARL aims at developing flexible perovskite solar cells with carbon electrodes.

PEARL – Flexible Perovskite Solar Cells with Carbon Electrodes

What is the project PEARL?

Flexible perovskite solar cells

Several advantages arise from the incorporation of carbon electrode in the perovskite solar cell (PSC) architecture such as reduced material cost, improved device stability and simplified device fabrication process as well as lower emissions.

Thus, the primary objective of PEARL is to realize flexible perovskite solar cells processed with industrially viable, scalable and environmentally sound methods, showing long term operational stability surpassing the IEC standards, efficiency of > 25%, lowered production costs below 0.3 EUR/Wp and minimal emissions < 0.01 kg CO2eq/kWh.

To reach these objectives, PEARL is focusing on the development of planar, conventional n-i-p, and further n-i-c, device architectures utilizing low-temperature carbon pastes as the top electrodes aiming to the emerging markets of building integrated photovoltaics (BIPV), vehicle integrated photovoltaics (VIPV) and internet of things (IoT).

News

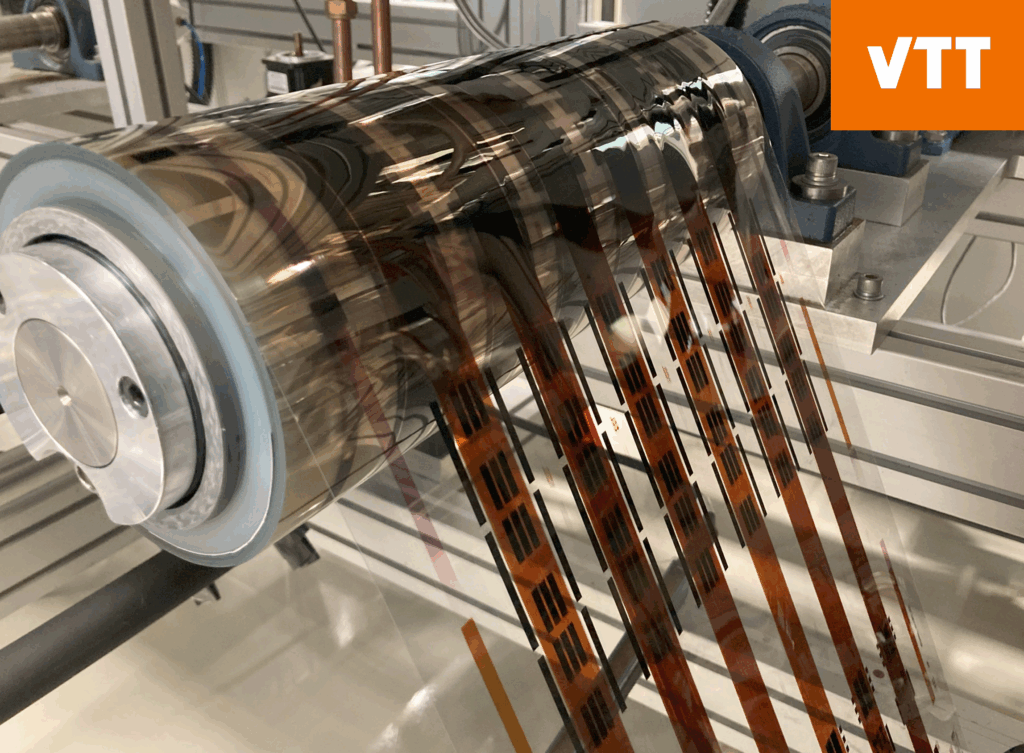

Milestone in Flexible Perovskite Solar Cells: EU-funded PEARL Consortium Demonstrates Roll-to-Roll Production

At month 18 of its three-year Horizon Europe project, the PEARL consortium has made decisive progress toward its target of 25% efficient, low-cost flexible perovskite solar cells with carbon electrodes. By combining cutting-edge materials research, pilot-scale roll-to-roll (R2R) manufacturing and comprehensive sustainability measures, partners across Europe have delivered a series of significant achievements.

Press release September 9, 2025

Flexible perovskite solar cell roll-to-roll processing at VTTs pilot line

© VTT Oy

PEARL project members during the Kickoff meeting at VTTs pilot line

© Fraunhofer FEP, C. May